P.O.Box 291

Purchase, NY 10577

U.S.A.

732-763-2814

help@usrenewableconsultant.com

We specialize in optimizing the design and deployment of such solar and wind power complimentary systems, to maximize their benefits. Our expertise will guarantee maximum results.

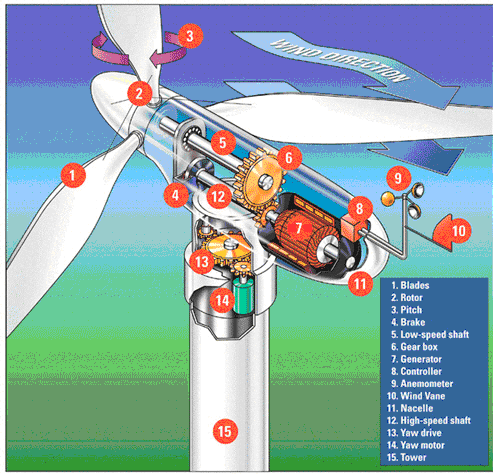

A typical small wind generator has rotor that is directly coupled to the generator which produces electricity either at 120/240 volt alternating current for direct domestic use or at 12/24 volt direct current for battery charging. Larger machines generate 3 phase electricity. There is often a tail vane which keeps the rotor orientated into the wind. Some wind-machines have a tail vane which is designed for automatic furling (turning the machine out of the wind) at high wind speeds to prevent damage. Larger machines have pitch controlled blades (the angle at which the blades meet the wind is controlled) which achieve the same function. The tower is of low solidity to prevent wind interference and are often guyed to give support to the tower.

As a general rule, wind generators are practical where the average wind speed is 10 mph (16 km/h or 4.5 m/s) or greater. Usually sites are pre-selected on basis of a wind atlas, and validated with wind measurements. Obviously, meteorology plays an important part in determining possible locations for wind parks, though it has great accuracy limitations. Meteorological wind data is not usually sufficient for accurate siting of a large wind power project. An 'ideal' location would have a near constant flow of non-turbulent wind throughout the year and would not suffer too many sudden powerful bursts of wind. An important turbine siting factor is access to local demand or transmission capacity.

Click this link to see a higher resolution US wind map.

Map of available wind power over the United States. Color codes indicate wind power density class.

This map shows the wind resource in the United States. Land is categorized by wind power class (left column of key), defined by a range of annual average wind speeds measured at 10 meters (33 feet) and 50 meters (164 feet). The columns called Wind Power estimate how much potential energy from the wind (in watts) is available per square meter of land, assuming wind turbine hub height of 10 or 50 meters. (Of course, to calculate Wind Power, assumptions about turbine size and performance were made.) Wind turbines are economical in wind power class 4–7.

The wind blows faster at higher altitudes because of the reduced influence of drag of the surface (sea or land) and the reduced viscosity of the air. The increase in velocity with altitude is most dramatic near the surface and is affected by topography, surface roughness, and upwind obstacles such as trees or buildings. Typically, the increase of wind speeds with increasing height follows a logarithmic profile that can be reasonably approximated by the wind profile power law, using an exponent of 1/7th, which predicts that wind speed rises proportionally to the seventh root of altitude. Doubling the altitude of a turbine, then, increases the expected wind speeds by 10% and the expected power by 34% (calculation: increase in power = (2.0) ^(3/7) – 1 = 34%).

Wind farms or wind parks often have many turbines installed. Since each turbine extracts some of the energy of the wind, it is important to provide adequate spacing between turbines to avoid excess energy loss. Where land area is sufficient, turbines are spaced three to five rotor diameters apart perpendicular to the prevailing wind, and five to ten rotor diameters apart in the direction of the prevailing wind, to minimize efficiency loss. The "wind park effect" loss can be as low as 2% of the combined nameplate rating of the turbines.

Utility-scale wind turbine generators have minimum temperature operating limits which restrict the application in areas that routinely experience temperatures less than 20°C. Wind turbines must be protected from ice accumulation, which can make anemometer readings inaccurate and which can cause high structure loads and damage. Some turbine manufacturers offer low-temperature packages at a few percent extra cost, which include internal heaters, different lubricants, and different alloys for structural elements, to make it possible to operate the turbines at lower temperatures. If the low-temperature interval is combined with a low-wind condition, the wind turbine will require station service power, equivalent to a few percent of its output rating, to maintain internal temperatures during the cold snap. For example, the St. Leon, Manitoba project has a total rating of 99 MW and is estimated to need up to 3 MW (around 3% of capacity) of station service power a few days a year for temperatures down to 30°C. This factor affects the economics of wind turbine operation in cold climates.

Onshore turbine installations in hilly or mountainous regions tend to be on ridge lines generally three kilometers or more inland from the nearest shoreline. This is done to exploit the so-called topographic acceleration. The hill or ridge causes the wind to accelerate as it is forced over it. The additional wind speeds gained in this way make large differences to the amount of energy that is produced. Great attention must be paid to the exact positions of the turbines (a process known as micro-sitting) because a difference of 30 m can sometimes mean a doubling in output. Local winds are often monitored for a year or more with anemometers and detailed wind maps constructed before wind generators are installed.

For smaller installations where such data collection is too expensive or time consuming, the normal way of prospecting for wind-power sites is to directly look for trees or vegetation that are permanently "cast" or deformed by the prevailing winds. Another way is to use a wind-speed survey map, or historical data from a nearby meteorological station, although these methods are less reliable.

Grid-tie systems are inherently simpler than either grid-tie with battery back-up or stand-alone solar systems. In fact, other than safety disconnects, mounting structures and wiring a grid-tie system is just solar modules with solar charge regulators, wind turbine with wind charge regulators and a grid-tie inverter! Today's sophisticated grid-tie inverters incorporate most of the components needed to convert the direct current form the modules to alternating current, track the maximum power point of the modules to operate the system at peak efficiencies and terminate the grid connection if grid power is interrupted form the utility.

Let us provide you with an assessment of your need.

We offer assessments ready to be taken to the bank for your Renewable Power Generation Home Improvement Loan. Contact us at: